Recently, KUNTAI Technology, a leading manufacturer specializing in Customization of Industrial Equipments, Sheet Metal Processing, Heaters, Humidifiers, and Air Conditioning Units, successfully reached a cooperation with a renowned pharmaceutical factory. The company provided a comprehensive air purification system worth $250,000, which includes one-stop solutions from design, installation to commissioning, perfectly meeting the stringent requirements for air quality in the pharmaceutical manufacturing process.

As an expert in Customization of Industrial Equipments, KUNTAI Technology took full advantage of its capabilities in Sheet Metal Processing to tailor the air purification system to the specific needs of the pharmaceutical factory. The system, which integrates advanced filtration technology, effectively removes contaminants such as dust, microorganisms, and harmful gases from the air, ensuring the production environment adheres to strict pharmaceutical industry standards.

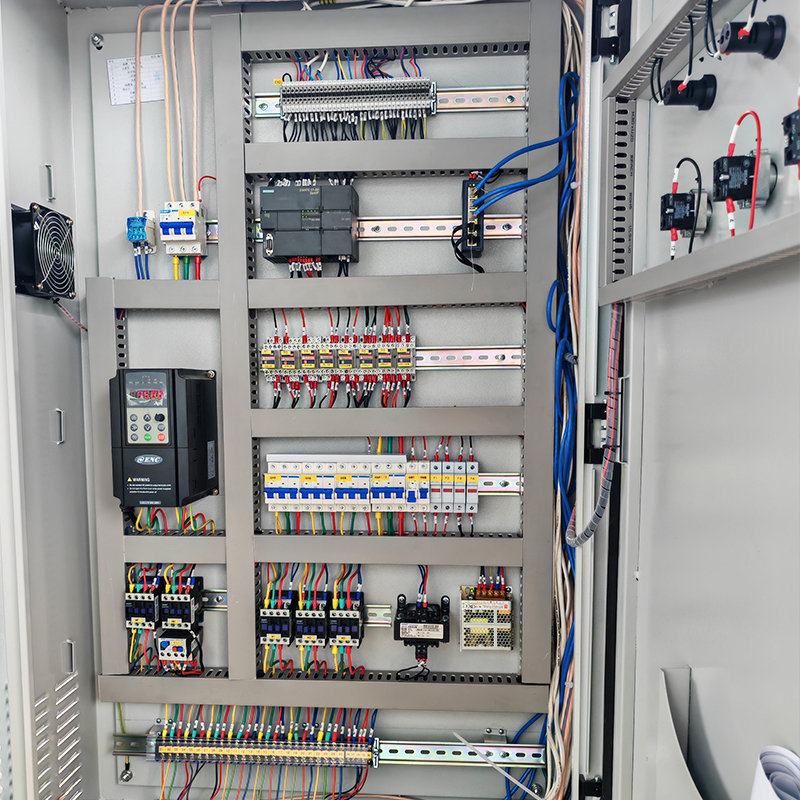

This state-of-the-art air purification system comprises high-efficiency particulate air (HEPA) filters, air circulation devices, and intelligent monitoring modules. Additionally, the system incorporates customized Heaters and Humidifiers produced by KUNTAI Technology, allowing for precise regulation of indoor temperature and humidity. These components, combined with the company’s top-notch Air Conditioning Units, provide a stable environment crucial for pharmaceutical production. The HEPA filters can remove over 99.9% of minute particles, ensuring the air entering the production area attains an extremely high level of cleanliness. The air circulation devices prevent the formation of air stagnation zones through uniform air distribution, while the intelligent monitoring module enables continuous tracking of air quality data and remote operation and management via terminals, keeping factory managers informed about system operations at all times.

During the project implementation, KUNTAI Technology's professional team collaborated closely with the pharmaceutical factory. They customized an air purification plan based on the factory's layout and production processes. Every aspect, from equipment selection, installation positioning to system debugging and optimization, was meticulously designed and rigorously reviewed, showcasing the company's proficiency in industrial equipment customization.

This collaboration not only demonstrates KUNTAI Technology's technical strength and professional capabilities in the field of air purification but also highlights its status as a reliable provider in Customization of Industrial Equipments, Sheet Metal Processing, and manufacturing of Heaters, Humidifiers, and Air Conditioning Units. As public concerns regarding drug quality and safety continue to rise, high-quality, customized air purification systems will become an essential means for pharmaceutical enterprises to safeguard production.